PC-ABS

1-2 Days

3D Printing Technology:

FDM 3D PrintingMaterial Info

Surface Look

Details

Strength

Flexibility

Colours:

Finishes:

Bead BlastingAbout our PC-ABS 3D Printing Material

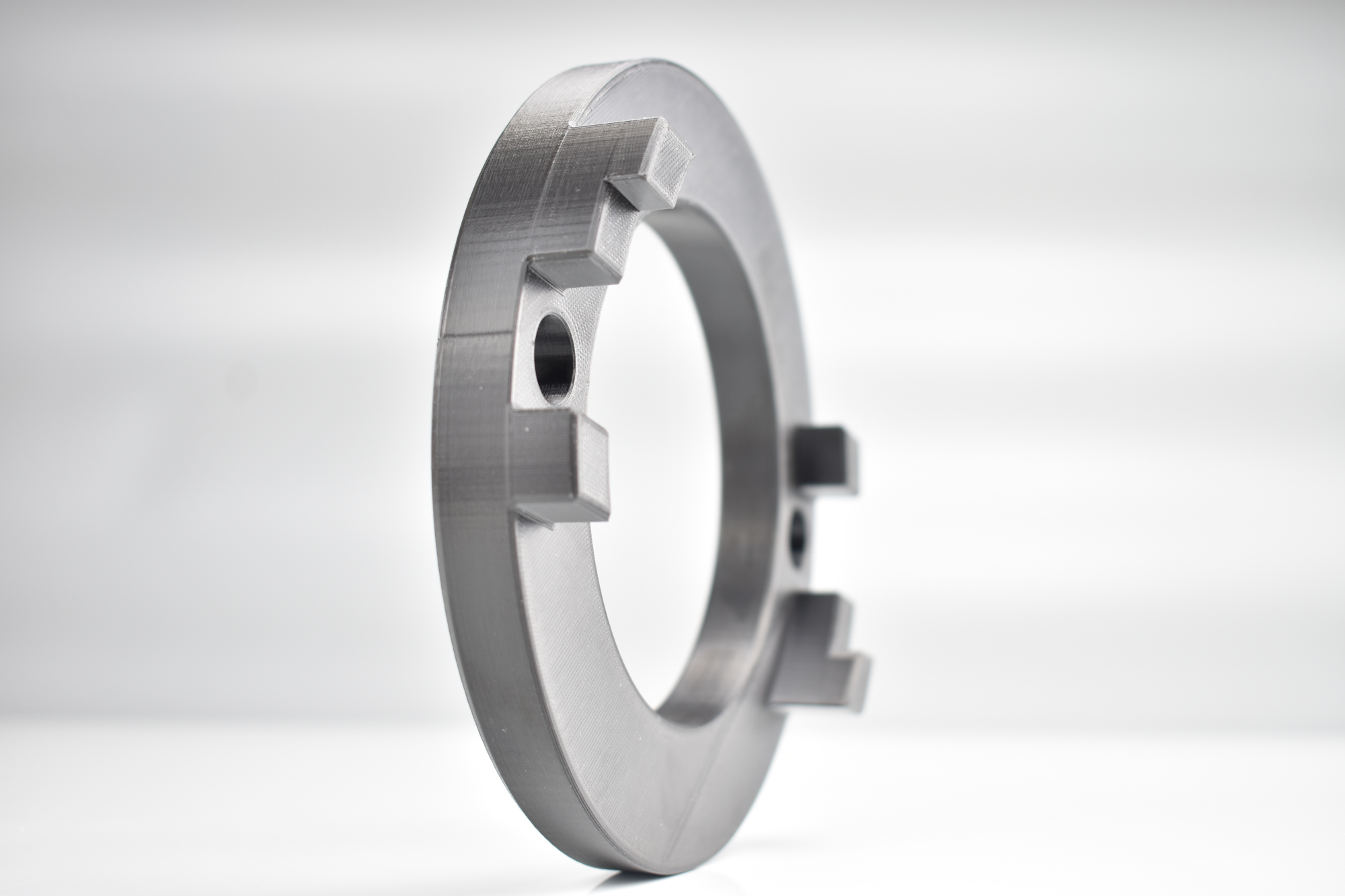

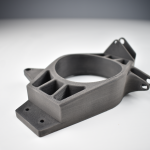

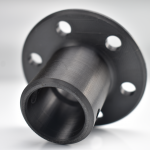

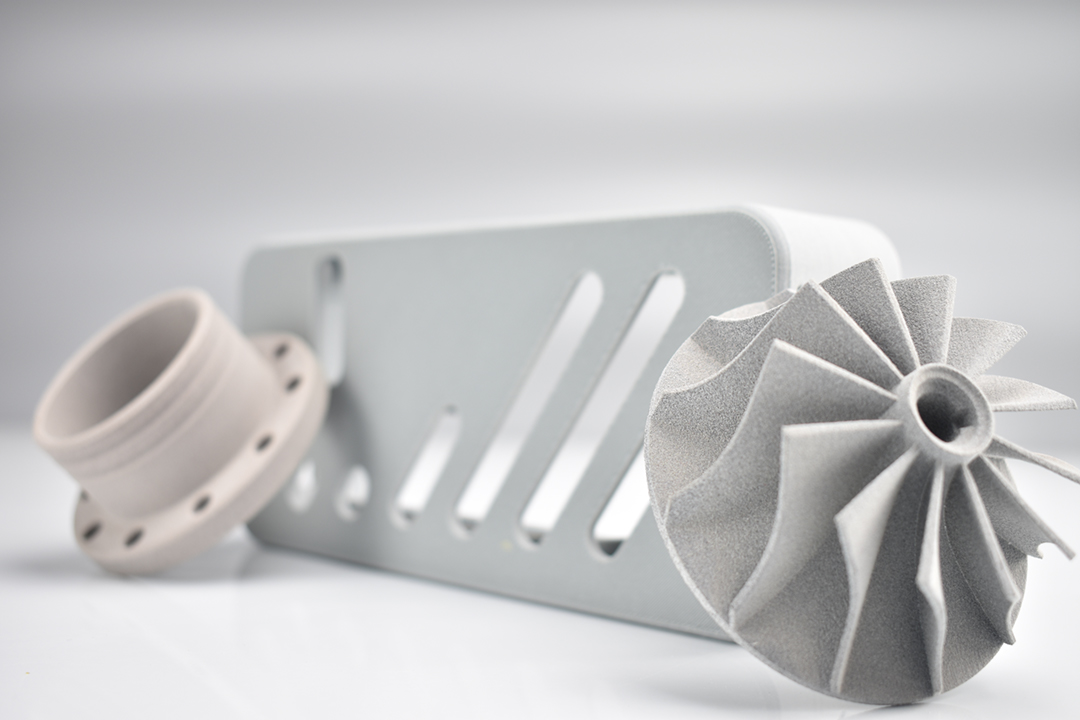

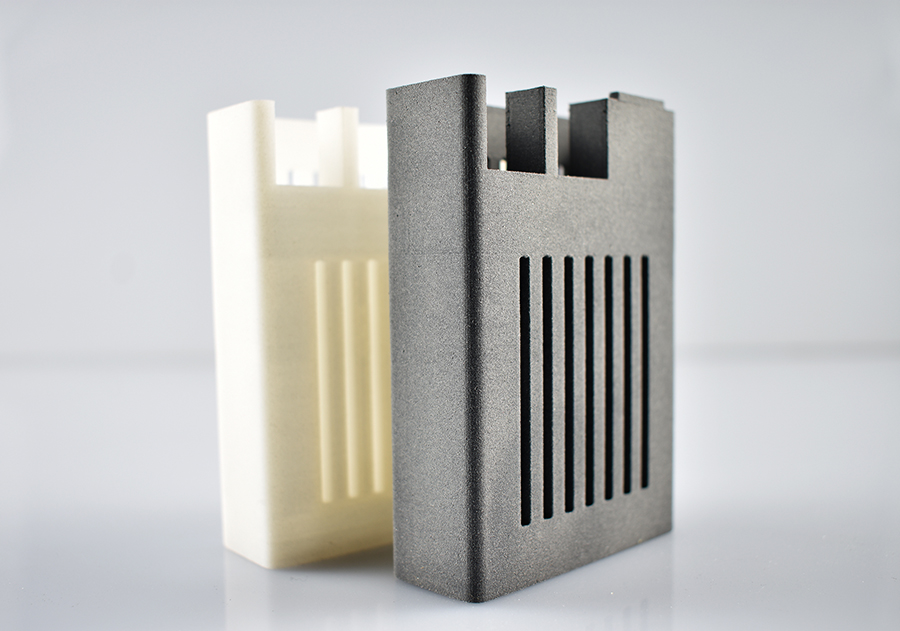

A blend of Poly-Carbonate and ABS plastics, this material is widely used across all industries for its toughness and versatility. Parts printed with PC-ABS exhibit a good level of flexibility and exceptional mechanical properties. Applications include batch manufacturing, jigs, working prototypes and electronic enclosures.

Models made with our PC-ABS material are easy to sand and post process.

Thanks to the quick turnaround provided by FDM technology, this blend of plastics is especially suited for fast product iterations within the automotive, aviation and electronics industries as well as full batches of parts and cases.

RECOMMENDED FOR:

✔ Fit & Form Testing

✔ Functional Prototypes

✔ Electronic Enclosures and Cases

✔ End User Products

✔ Batch Manufacturing

✔ Jigs and Fixtures

NOT SUITABLE FOR:

✘ Jewellery Design

✘ Small and Detailed Art Models (eg. Miniatures and Gaming)

✘ Designs with Large Curved Surfaces (eg. Spherical Objects)

PC-ABS SPECIFICATIONS:

Accuracy: ±0.2% (with a lower limit of ±0.2 mm)

Max Size: 300 mm by 300 mm by 300 mm

Layer Height: 0.20 mm Standard – 0.14 mm High Detail

Infill Options: 20% Standard – 80-100% High Infill

Heat Resistance: Up to 100 C

When to use our PC-ABS 3D Printing Material

Take your ideas to life at unprecedented speed, iterate and test your designs with ease.

3D print your electronic enclosures with our industry leading materials for real life applications.

Print up to 5000 parts in a matter of days with no tooling costs.

Design Guide

≥ 0.6 mm

Wall Thickness

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

≥ 1.6 mm

Unsupported Wall Thickness

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

≥ 3 mm

Pillar Diameter

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed Details

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved Details

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

≥ 0.4 mm

Clearance Between Parts

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Supports Required

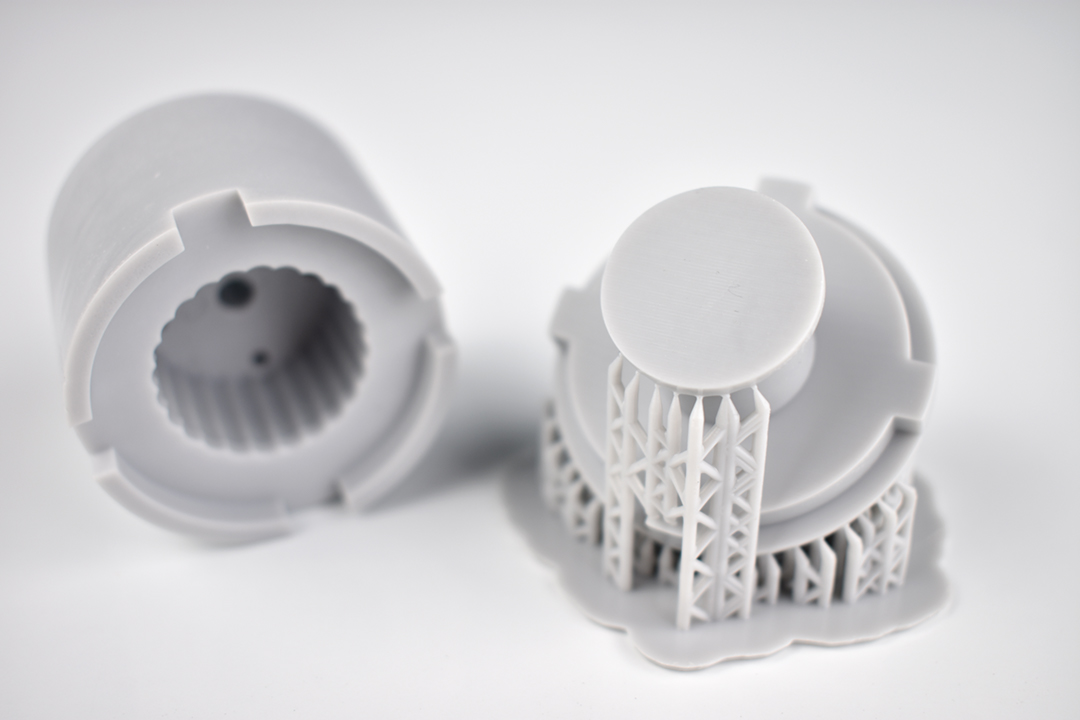

Our PC-ABS requires supports in order to print overhanging areas.

It's important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.