High Detail Resin

5-6 Days

3D Printing Technology:

SLA 3D PrintingMaterial Info

Surface Look

Details

Strength

Flexibility

Colours:

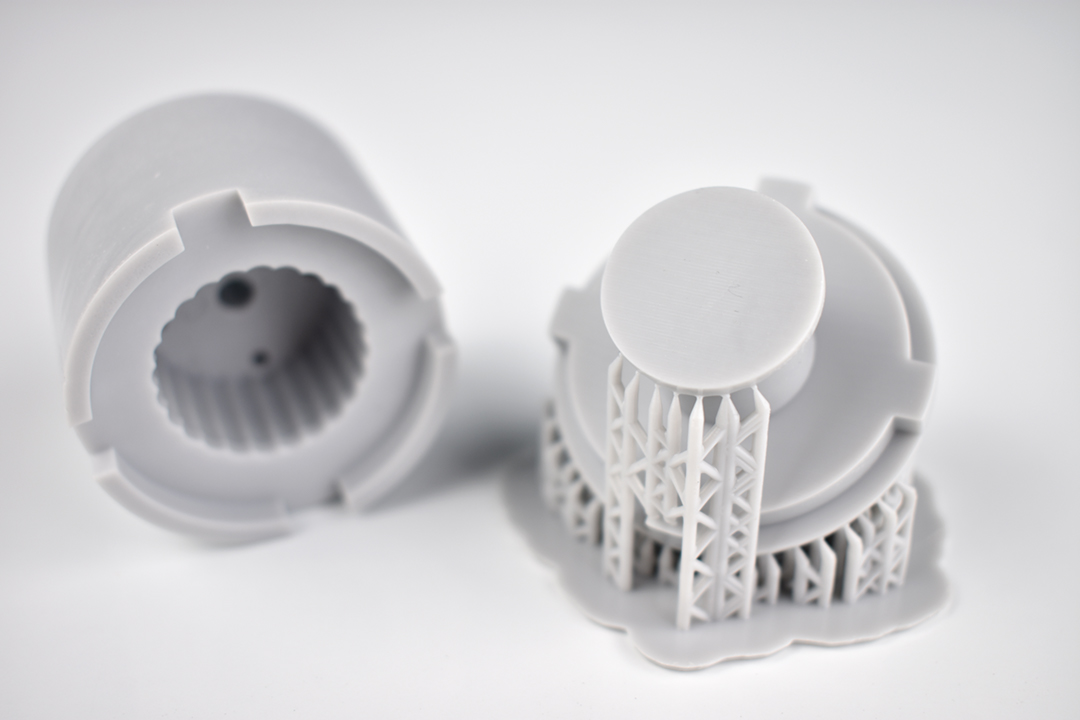

About our High Detail Resin 3D Printing Material

Our High Detail Resin material exhibits a smooth surface finish with crisp details and good elasticity. The material is particularly suited for small and intricate models, perfect for testing your jewellery designs and producing stunning miniatures. The finished product is easy to sand and paint.

RECOMMENDED FOR:

✔ Jewellery Design

✔ Miniatures and Gaming

✔ Art Models

NOT SUITABLE FOR:

✘ Jigs and Fixtures

✘ Functional Prototypes

HIGH DETAIL RESIN SPECIFICATIONS:

Accuracy: 50 micron XY

Max Size: 132 x 74 x 175 mm

Layer Height: 0.50 mm Standard

Infill Options: 100% Solid

When to use our High Detail Resin 3D Printing Material

Test your precious designs before moving into production.

The perfect application for tabletop gaming and miniatures

Design Guide

≥ 0.6 mm

Wall Thickness

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

≥ 1.2 mm

Unsupported Wall Thickness

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

≥ 2 mm

Pillar Diameter

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 2 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

≥ 0.4 mm Thickness

≥ 0.2 mm Depth

Embossed Details

Embossed details should have a minimum line thickness of 0.4 mm and a depth of 0.2 mm or higher.

≥ 0.4 mm Thickness

≥ 0.2 mm Depth

Engraved Details

Engraved details require a minimum line thickness of 0.4 mm and a depth of at least 0.2 mm.

≥ 0.4 mm

Clearance Between Parts

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Supports Required

Our High Detail Resin requires supports in order to print overhanging areas.

It's important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.