Top 5 Cad Parametric Software For Engineers And Designers

Wondering How To Get A Great 3d Print? Start With A Great Cad Software!

From its humble beginnings as a MIT project in the early 60’s, CAD or Computer Aided Design has come a long way to occupy today a central role in every major engineering venture. From the most renown product design companies to aerospace and automotive almost every industry revolves around the use of one of these packages throughout the prototyping and manufacturing processes.

As 3D printing technologies keep growing approaching mass manufacturing the ability to translate ideas into everyday products is now more than ever dependant on the right CAD software and here are our top 5 picks!

Solid Works

No need for presentations here! SolidWorks is one of the most popular choices for designers and engineers around the world.

Developed by Dassault Systèmes in the early 90’s the adoption of this software has been steadily growing boasting today the largest community in the CAD industry.

SolidWorks leads the pack when it comes to handling large and complex assemblies which, together with the super-intuitive user interface, makes this the ideal CAD package for every product designer.

Dassault Systèmes offers a range of suites targeting a wide range of applications like CAM, injection moulding and PCB design to name but a few.

It’s also worth mentioning the recently introduced topology optimization tool to take full advantage of the most advanced additive manufacturing solutions.

Fusion 360

What if you could work with a software that seamlessy integrate product design and manufacturing?

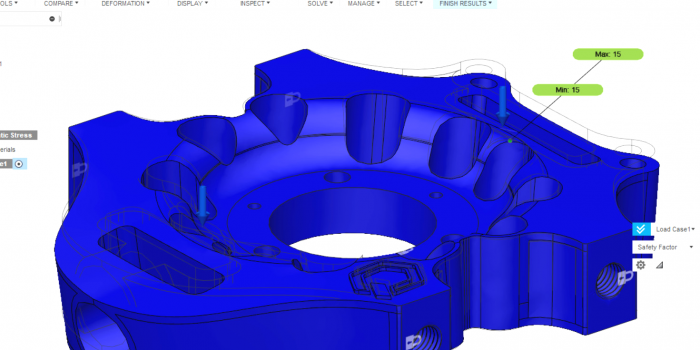

Well you guessed it! Autodesk Fusion 360 is definitely a top pick to easily manage the product development cycle from inception to 3D printing and production.

This CAD package has gained a lot of traction in the last 5 years mainly for its ease of use and innovative features being one of the first Cloud based software in the industry.

Perfect for beginners and experienced users alike this tool offers parametric and surface modelling alongside analysis and rendering environments.

From an additive manufacturing perspective the team and community behind Fusion have been working hard to stay ahead of the game with the recent addition of an intuitive generative design tool that allow users to create lightweight structures ready for the next industrial revolution (OK no hype but it’s still pretty cool).

There are some downside however when handling large assemblies where the program can get sluggish and sometimes a bit frustrating.

CATIA

Catia was first developed in the 70’s by Dassault Aviation in order to build the Mirage fighter jet.

Some 4 decades later this software is still the first choice for aviation , marine and automotive giants across the world.

Still part of the Dassault Systèmes family this CAD suite offers a higher level of control for large and complex assemblies over SolidWorks with advanced analysis tools that allow engineers to simulate how vehicles, planes and ships behave in real world situations.

Catia is also renown for its powerful surface modelling environment that seamlessly connects to the parametric features.

While this is one of the best packages on the industry scene to date the license and subscription fees could be quite overwhelming for a young startup or single users and somewhat of an overkill for simpler product design projects.

Auto Desk

Part of the Autodesk family, this parametric modelling software offers everything you need to bring your products to life.

Often compared to SolidWorks in terms of functionality this platform boasts a range of functionality that makes it the perfect choice for fabricators, tool designers and injection moulding companies.

The UI is intuitive however the learning curve is more steeper than its younger brother Fusion 360.

The software handles large assemblies with ease and includes all the analysis tools and manufacturing integrations you would expect from a professional CAD suite.

Converting a file to a 3D printing ready format is quick and easy with the possibility of connecting Fusion 360 generative design tools to create stronger and lighter parts made possible only by the newest 3D printing technologies.

Siemens NX

Backed by one of the biggest technology groups in the world this is more than just a software, it’s a design and manufacturing system that manages the whole production cycle from prototyping to commercialisation.

This platform offers parametric modelling coupled with a series of smart direct modelling tools, this means that large assemblies can be continually updated and reviewed without fear of losing or damaging previous design features.

Directed to professionals and engineering companies across the world the suite also offers a range of add-ons including a wide set of analysis tools and additive manufacturing solutions.