Is Your Model Ready For 3D Printing?

A good print starts its life as a stunning design. Additive manufacturing has the potential to revolutionise the way we make pretty much everything. To harness the advantages of this technology we’ve put together a set of guidelines to get the best results out of your models. Here you’ll find the most important factors to consider when designing for FDM printing.

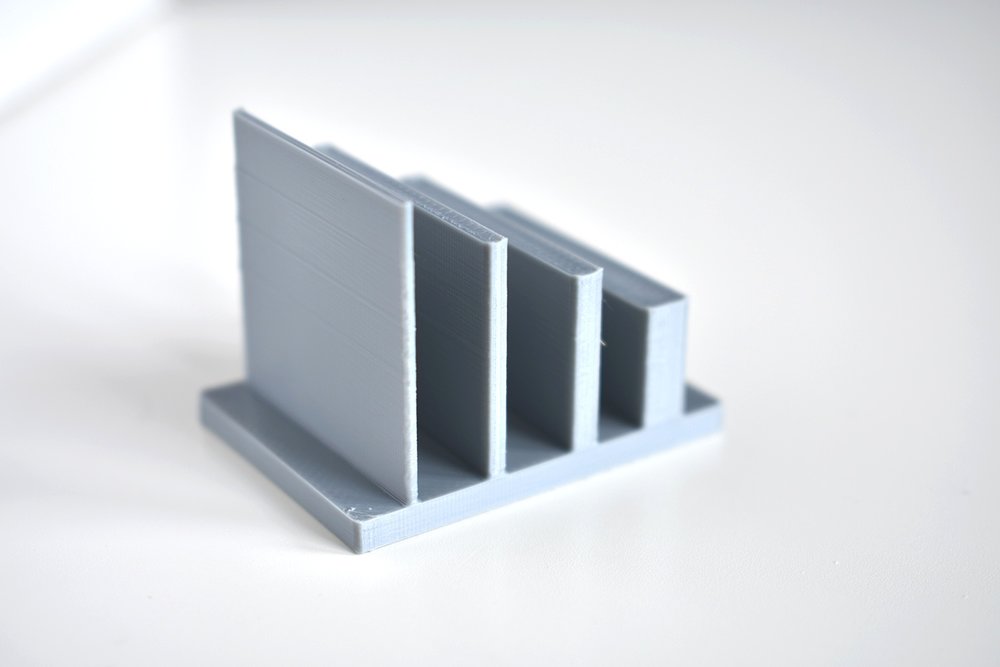

WALL THICKNESS

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be.

We always recommend designing walls with a thickness of at least 1 mm.

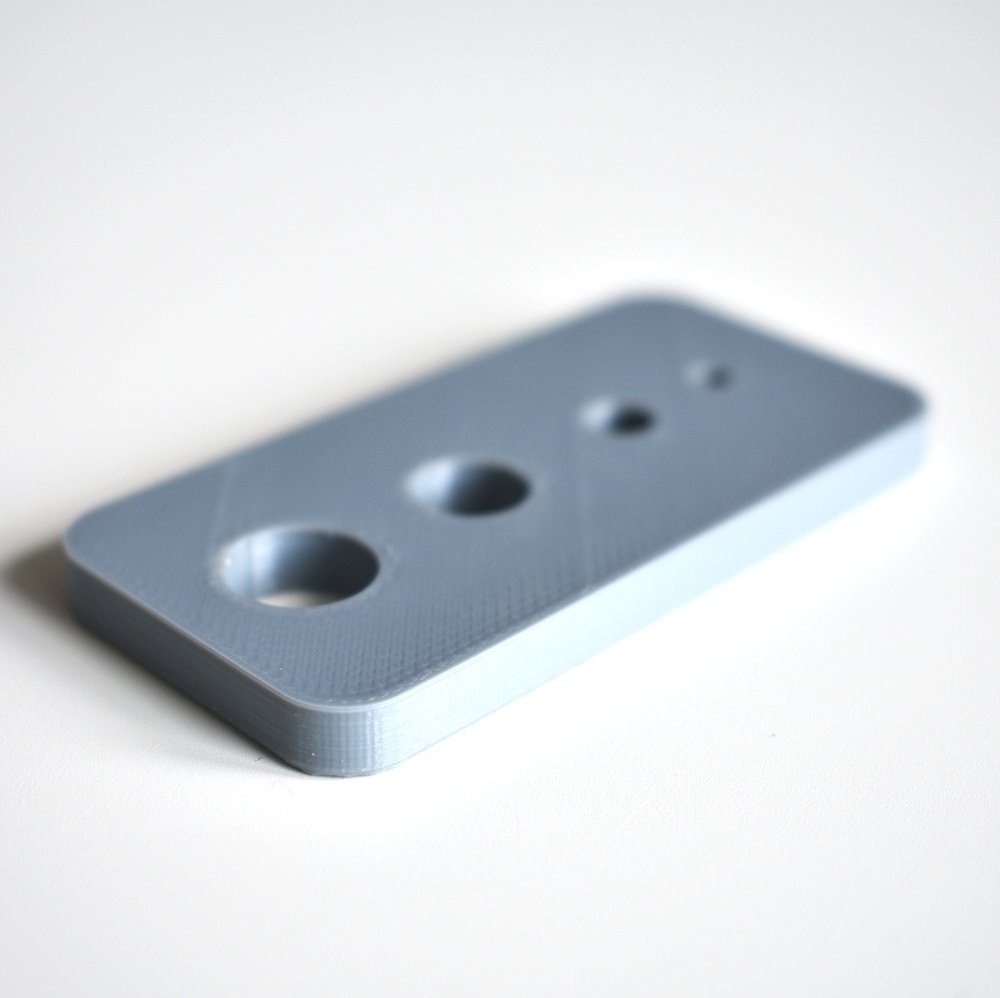

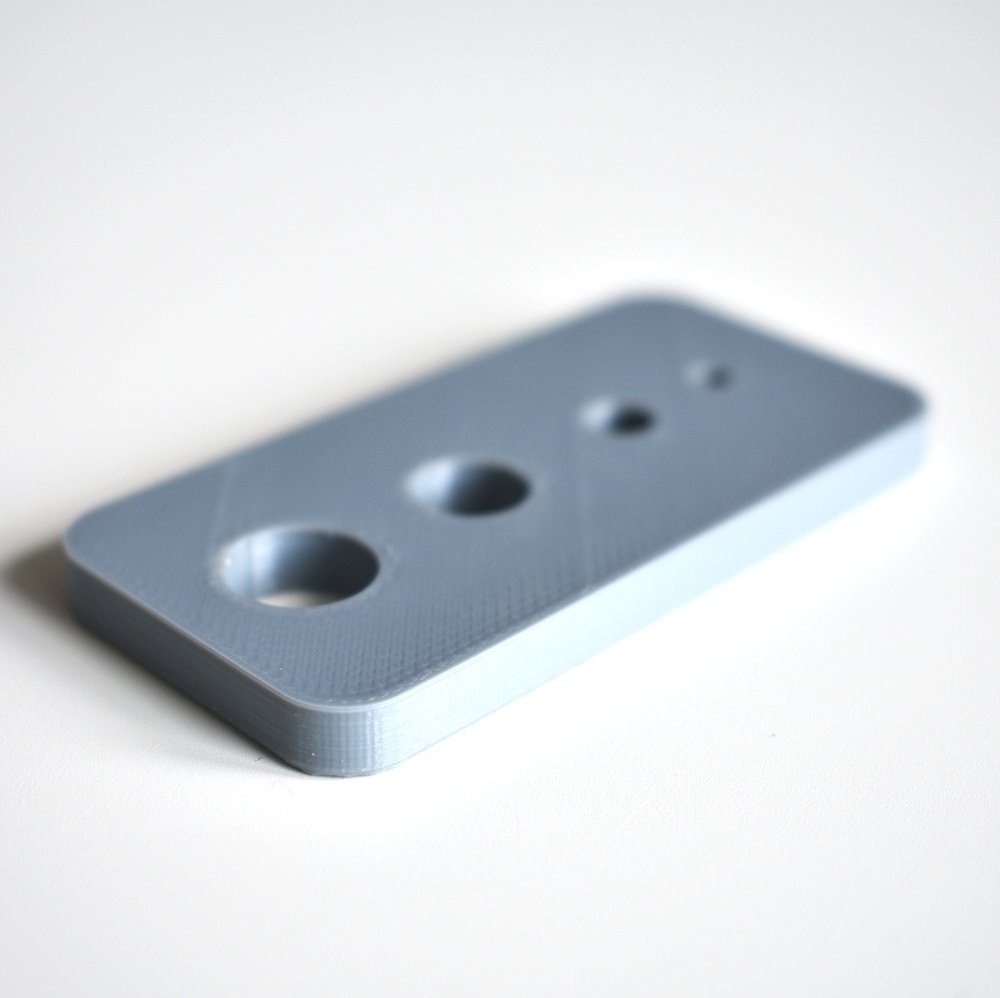

HOLES

This is another feature present in almost every model especially jigs, fixtures and mechanical parts.

We recommend designing holes 2% to 4% larger than the desired diameter.

When dimensional accuracy is paramount we suggest using design smaller diameter holes and drill to the correct dimension once printed.

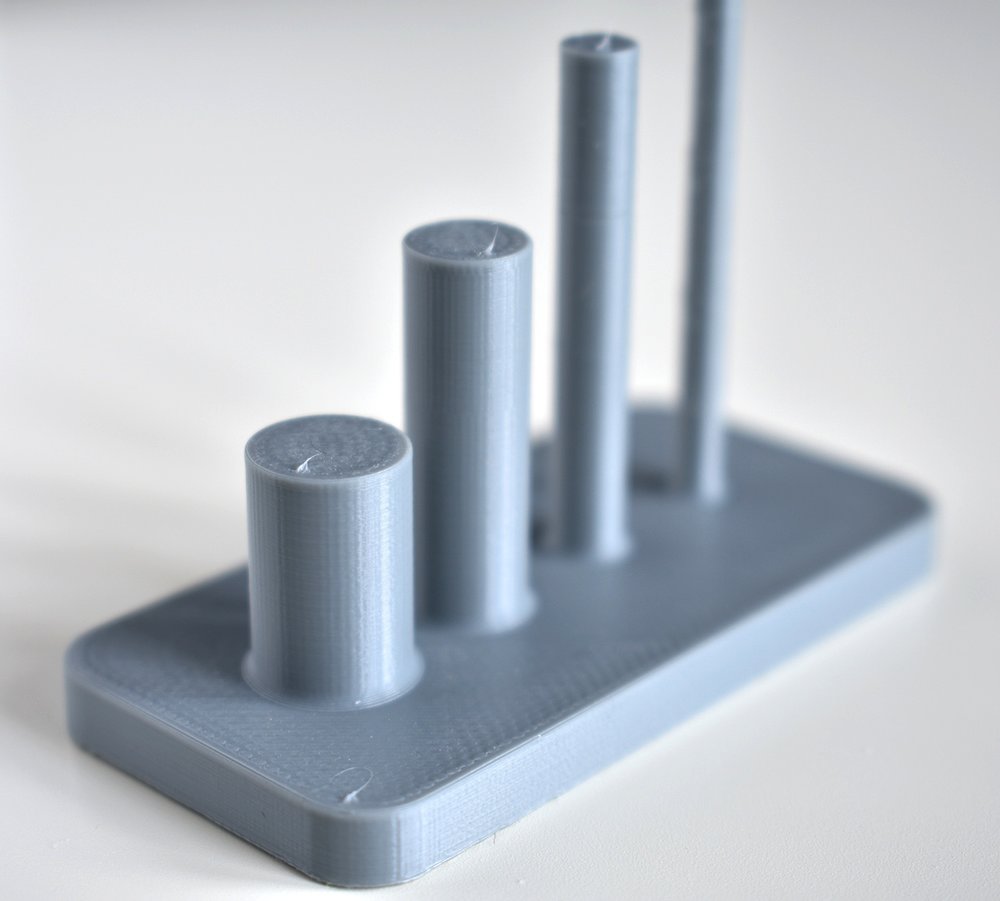

PINS

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

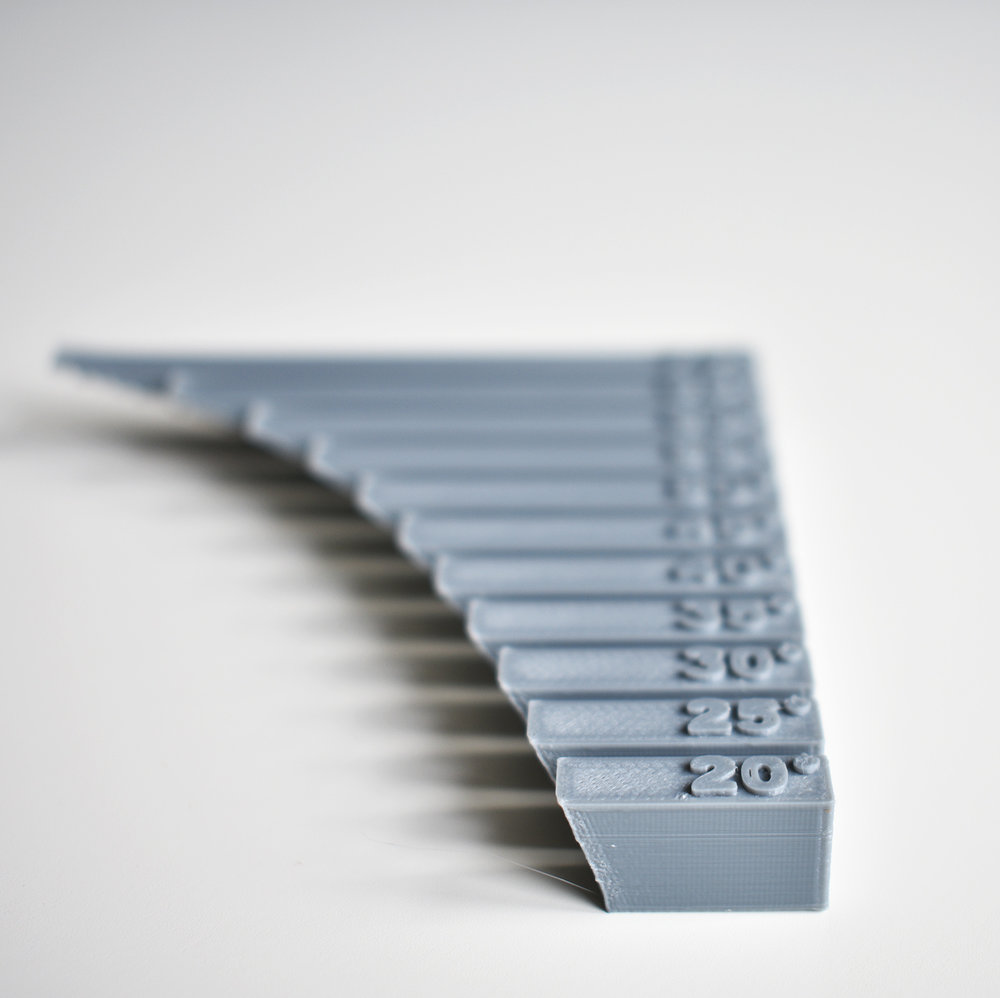

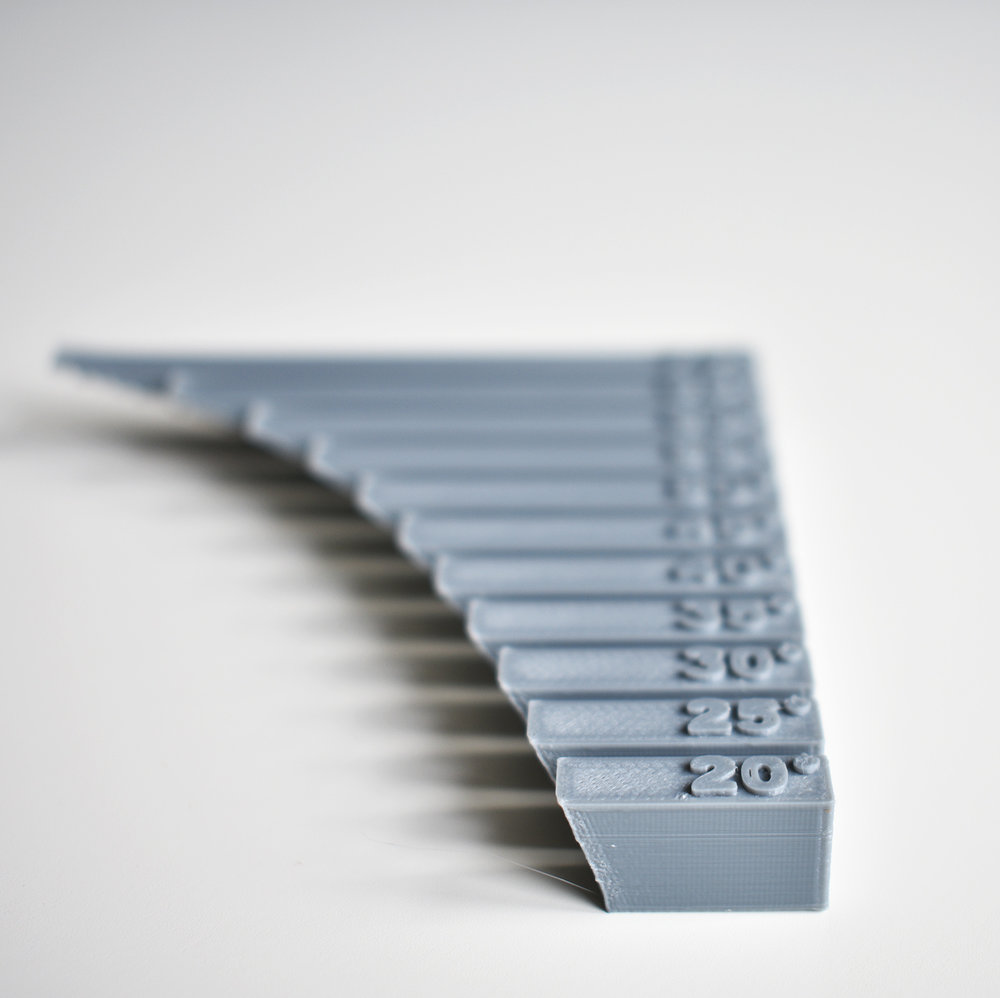

OVERHANGS

This is, without a doubt, one of the most important factors when designing a model.

In general you want to avoid unsupported features at angles greater than 45 degrees.

Yes, supports can go a long way but remember that these will need to be manually removed from the final print often leaving small marks and imperfections.

If you think your model might need a bit of a touch up check out our finishing services.

EMBOSSING/ENGRAVING

In general, engraved details need a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

For engravings we are looking at 2.5 mm line thickness and a minimum depth of 0.5 mm.

Now that you’re all set for the perfect 3d print upload your model here or get in touch today at [email protected] and get our design experts to help you out with your project.