Which 3D Printing Material Should You Choose?

Additive manufacturing brings a whole range of advantages compared to traditional manufacturing from the prototyping stage through to mass production however to make the best out of this technology we need to understand what is the most suitable material for your application.

Today we’ll guide you through our industry leading materials to help you make the right choice for your next project.

Standard ABS plastic

Certainly the most used 3d printing material in the industry. Stronger and more resilient than PLA our ABS offers a smooth and matte finish with good impact resistance and elasticity.

This remains the cheaper option for your printings however we suggest using this material for smaller prototypes due to its tendency to warp over long and flat surfaces.

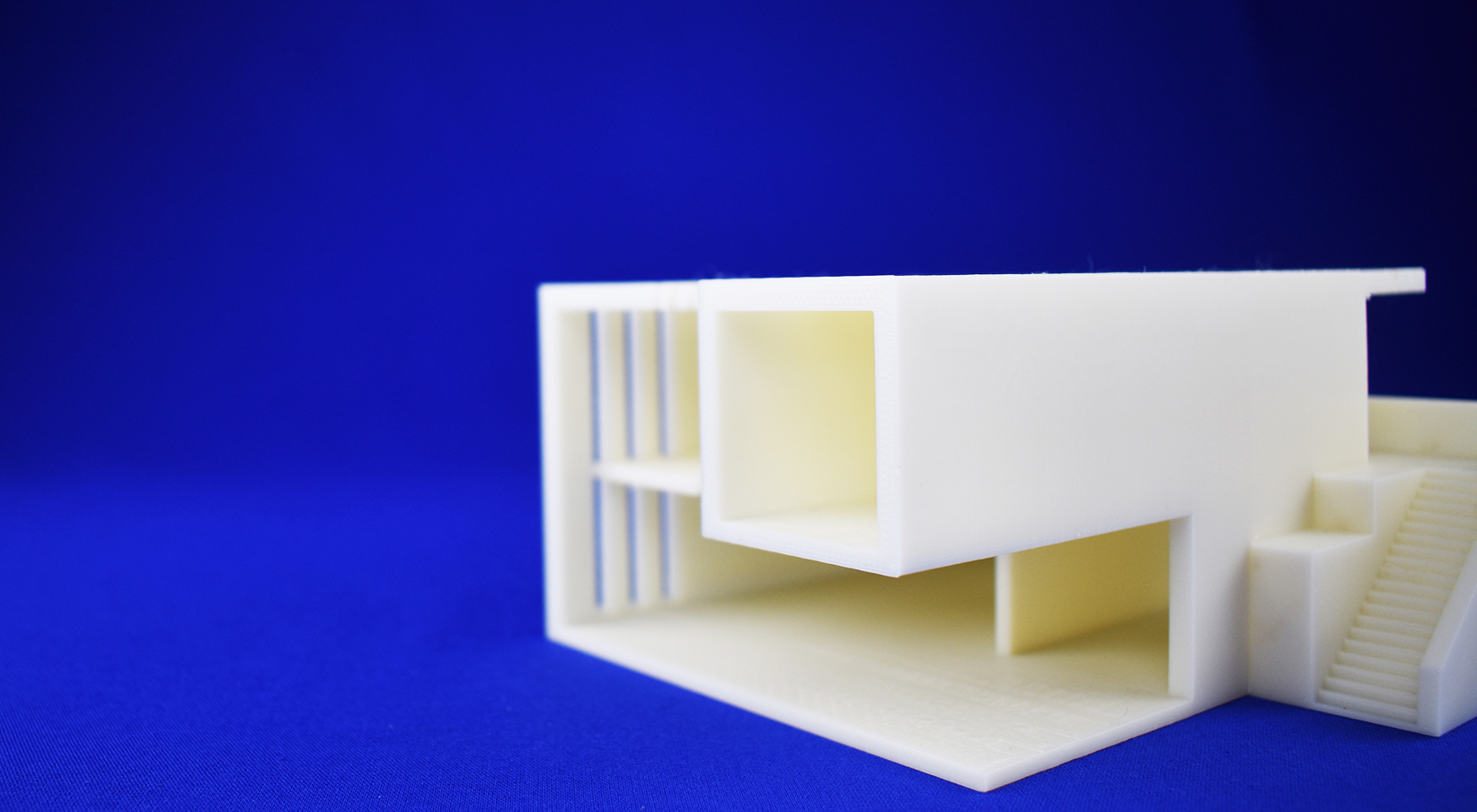

Engineering Plastic

This is our proprietary blend of ABS and poly-carbonate. Simply put this is the best option for all of your prototyping needs with high impact strength and elasticity.

The finished products have a semi-matt look and can be easily sanded and post processed ideal for showcase models and fit & function parts.

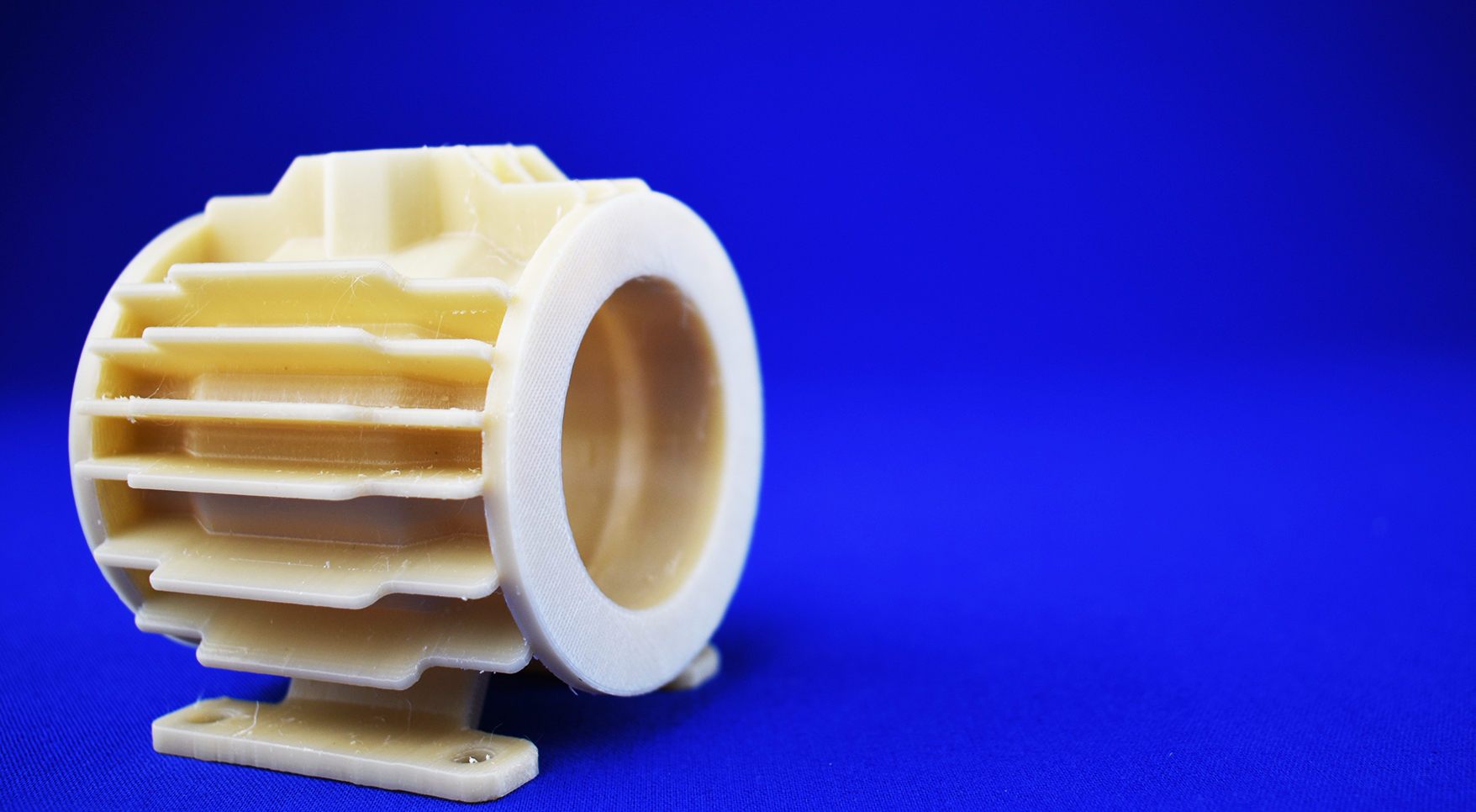

PC-ABS

One of the toughest materials available on the market this blend has a much higher percentage of poly-carbonate compared to our engineering plastic making it perfect for end user parts, casings and tools ready to be used on the factory floor.

Flexible TPU

The perfect combination between elasticity and toughness this 3d printing material boasts an impressive resistance to abrasion and heat making it the best choice for the automotive, aviation and manufacturing industry.

Need a custom manifold or gasket for your project? Look no further this is the material for you.

Get in touch today for a free consultation or upload your 3d model here for an online quote and don’t forget to follow us for more tips, news and tutorials from the 3d printing world.